McKenzie Tray Dryer Overview (Expandable Model)

The McKenzie tray dryer blurs the separation between cabinet dryers and tunnel dryers. The McKenzie is unique in that it has a small footprint, and yet utilizes dollies carrying trays, like the much larger systems. This combination allows the McKenzie to conduct batch, batch-to-dry, counter-flow, and parallel flow dehydration protocols, all with the same system. The McKenzie is expandable, and can double in capacity, with minimal additional investment. Versatile and effective the McKenzie is an outstanding choice.

Features/Benefits

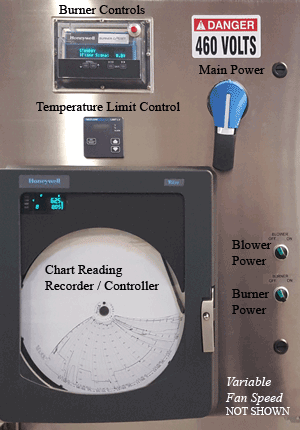

- UL EPH approved for food sanitation safety

- 1 million BTU burner for natural gas or propane fuel source.

- Double-walled stainless steel insulated construction helps provide uniform and consistent drying while helping reduce operating cost

- Each tray is 27-in. x 38-in. (68.58 cm x 96.52 cm), 34 trays per stack with 6 carts.

- Each tray will allow 6.68 sq. ft. (.62 sq m) of product space.

- Each expansion can add an additional 4 carts. Fully expanded dryer holds 18 carts.

- Each tray is 24-in. x 38-in. (60.96 cm x 96.52 cm), 42 trays per cart with 6 carts.

- Each tray will allow 6.33 sq. ft. (.59 sq m) of product space.

- Each expansion allows 4 more additional carts. A fully expanded dryer has triple the original capacity of a standard version. Total is 18 carts with 756 trays, 4785.48 sq ft.

- The McKenzie uses a 15 HP fan for high air velocity. This produces approximately 50,000 Cubic Feet per Minute (1415.84 Cubic Meters per Minute).

- Requires ducting for exhaust (out) and fresh air intake (in).

- This unit is capable of an automated humidity control system (recommended).

- Maximum operating temperature of 220°F/104°C.

Specifications

Dryer Dimensions

- Each extension is 7-feet, ½-inch (2.13 m, 1.27 cm) long.

- A maximum of 3 Extensions making the total length 38-feet, 7 7/8-inches.

- Expandable from 1,595 sq. ft. (148.18 sq m) to over 4,785 sq. ft. (444.54 sq m).

NOTE: Optional AHCS (Adjustable Humidity Control System) recommended to lower operational costs.

Operation Costs |

||||||

|

||||||

- Telfon Liners

- Digital Thermometer

- Choice of Data logger or Chart Recorder

- Tray Cart

- Extra set of trays (solid or perforated)